Clever redesign of packaging can save on all aspects of storage. Smaller, stronger packs and appropriate use of materials often lead to better palletisation, stacking, frequency of supply and storage requirements.

Case Studies

Review our Case Studies of other clients. Smaller, stronger packs and appropriate use of materials often lead to better palletisation, stacking, frequency of supply and storage requirements.

Request a Quote

Neal Brothers Packaging can help you save costs at every stage of your supply chain. With nearly 100 years of experience we are confident we can deliver custom packaging that rise above your expectations.

Value Added Packaging

Clever redesign of packaging can save on all aspects of storage. Smaller, stronger packs and appropriate use of materials often lead to better palletisation, stacking, frequency of supply and storage requirements.

Case Studies

Review our Case Studies of other clients. Smaller, stronger packs and appropriate use of materials often lead to better palletisation, stacking, frequency of supply and storage requirements.

Request a Quote

Neal Brothers Packaging can help you save costs at every stage of your supply chain. With nearly 100 years of experience we are confident we can deliver custom packaging that rise above your expectations.

Design

Computer aided design & modelling has transformed packaging from a process bolted on during the despatch function to a strategic element that has profound effect on the performance of a supply chain.

Test

Approved to ISO 9001:2015 Neal Brothers design team ensure that all packs are designed with cost effective performance in mind.

Manufacturing

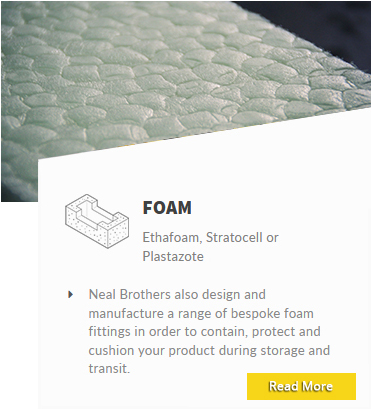

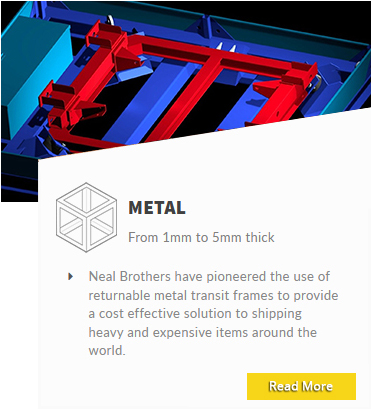

Neal Brothers produce the most economic packaging required, by minimising waste, within the shortest lead times, in accordance with ‘Just in Time’ requirements in one of our three factories.

Supply

Experienced on-site export packing teams, despatch department implants, own transport and freight forwarding complete the picture.

NEAL BROTHERS

PRODUCTS & INFORMATION

![]()

EXPORT PACKING LINKS

PACKAGING LINKS

ABOUT US

The origins of Neal Brothers export packers date back over 100 years. During that time the business has expanded from its base in Leicester to operations throughout England and in Europe, North America and South Africa and with its strategic partnerships can offer full logistics and packing services worldwide.

Quality of service has always been a priority for Neal Brothers and continued growth has enabled the company to employ the best people and invest in the best technology and equipment.